|

Scratchbuilding Your Model Railroad Structures

Scratchbuilding (making model buildings from scratch) is the art of creating structures or other models out of raw materials – sheets or strips of plastic or wood, glue, paper, cardboard, etc. Some fantastic buildings, locomotives and railcars can be built very inexpensively and without requiring much more time than it takes to build and paint a kit. There are many benefits to scratchbuilding as previously outlined on the “Buildings” page.

Planning Your Scratchbuilding Project

So, how do you go about doing this? How do you create a model building from scratch?…

First, you have to plan…

What type of model railroad structure do you want to build and why?

• How will it fit into your layout theme, era and locale?

• Will it be based on a particular prototype?

• How much space do you have for it?

• Will it need to be close to the tracks?

• Will it require a track on both sides or through the middle?

• Does it need a sidewalk, road, dock, or parking lot?

• What are the dimensions?

After you answer these questions, draw the model building out on paper, or with your CAD program if you have one.

Label the drawing with proper dimensions in the scale you’re using. If the model you are scratchbuilding is based on a prototype, make sure you have a picture of the original structure from several viewpoints, along with the actual dimensions of the prototype, so you can make the model as realistic as possible. The true dimensions of the structure can be easily converted to the scale that you wish to model. If you're making an HO building, for example, you would divide the prototype dimensions by 87; if N Scale, divide by 160; if O Scale - divide by 48, and so on. See the Scales page for more information.

If you would rather use a plan that has already been created, you may want to visit the Scale Model Plans website which is dedicated to creating and selling plans for scratch-building projects.

Once you have selected, or designed, a structure on paper or on the computer, you can use the materials and scratchbuilding techniques described below to build it; or you could use a laser cutting service, or even your local sign shop to create the parts.

If you would like to get your hands dirty and learn how to do this yourself, which of course, happens to be the most economical way as well, then read on to learn some basic techniques upon which you can grow and even create some of your own techniques. Don't be afraid to experiment. And don't worry if your first attempt isn't that great. Each time you try, you will get better. Soon, you will be doing your own clinics at the NMRA Convention.

Scratchbuilding Materials

The substructure can be made with styrene, which is probably the most commonly used material for scratchbuilding. You could also use mat board (the material used in photo framing), gel foam or balsa wood. These latter materials are easier to cut but perhaps not as durable as styrene. The wood may be more suitable for larger scales, like S and O. Laserboard is also becoming popular now as a more realistic material to use in scratchbuilding structures. Textures.com is a also good place to look for scratchbuilding materials.

Scratchbuilding Methods

To cut styrene to make substructure walls for your model building, use a metal straightedge and a scribing tool. Scribe along the line to be cut several times, and then pick up the styrene and bend it forward to snap it at the scribed line.

To make window and door openings, first draw on the styrene where you want these to be, extending the lines to the edges of the styrene on both sides. Scribe and snap the styrene at these lines. Discard the pieces where the openings will be and glue the other pieces back together on a flat surface.

|

TIP from a visitor...

This allows the opening to be snapped out without having to glue the rest of the wall back together. Use a small file to clean up the opening. Much less work!" - from Russ Venlos |

Once the substructure walls are completed, you can glue on a trimmed sheet of purchased embossed vinyl or plastic masonry or siding (produced by Plastruct, Kibri and others). This sheet should be a little larger than the substructure so that when you glue the walls together there won’t be a gap at the corners. (Or, after the building is put together, you could just glue on trim-corner-strips to cover any irregularities in the corners.) After the sheet is glued on, use a hobby knife to carefully cut out the openings for the windows and doors.

Another option for this step is to use various types of graphics that have been designed (by Evans Designs) for use on model railroad buildings. You can purchase the software that contains a huge selection of wall coverings and details that can be placed over the styrene walls that you've made to bring them to life.

If your model will be entered in a contest, it would be best to use your own materials for the walls and roof, rather than plastic or printed sheets, as described below.

The windows and doors for your model building can be purchased separately from a company like Grandt Line, which is what I would recommend, especially if you are modeling in N or Z scale. If you are going to be using purchased windows and doors, you will have to measure your openings and cut them so the windows will fit.

If you’re working with larger scales, you can scratch build these items if you wish.

To make your own windows…

• You will need styrene strips measuring a scale 1x4, 2x2, and ½ x1 inch purchased from a company like Evergreen. (It's very helpful to also have on hand a cutter, like the Northwest Short Line Chopper to help make clean cuts on these styrene strips.)

• Use 1x4’s to frame the inside of the window flush with the siding. Then glue on a 2x2 sill and 1x4 trim around the outside of the window.

• Then use 2x2’s the make the inner frame trim around the sides and the top of the window.

• Use 2x2’s to make the upper and lower sashes for a double-hung window. Start by making the 2 frames for the sashes, and then add the inner trim (mullions) using the ½ x1 strips (for the edges of the window panes).

• Glue the upper sash in place against the back of the 2x2 trim.

• Then glue the lower sash in the window from the back overlapping the top of upper sash.

• Then you can paint the window and the frame.

• Use small trimmed pieces of acetate for "glass" and glue these to the backs of the windows. (The clear plastic tabs on file folders or the clear plastic used for name badges or any other clear plastic sheets work well for this. If you can find the plastic sheets that have a frosted appearance on one side, that may be even better, especially for lighted buildings because it diffuses the light and you can't see inside.)

Scratchbuilding Doors…

• Use scale 1x4 strips for the frame for inside the doorway.

• Put a 2x4 sill along the bottom.

• Use a sheet of 0.02" styrene to make the door.

• Add a 1x6 strip to the bottom of the door, then 1x4 strips along the sides and top.

• Use 1x4 strips to make the inner door trim in the shape of an upside-down cross.

• Use strips of 2x2’s as door-stops on the door frame across the top and down both sides.

• You can then paint the door and glue the head of a pin on the door to simulate a doorknob.

Putting it all together

After you've installed the windows and doors, you're ready to glue the walls together.

It's extremely helpful for all your model building projects to use a magnetic gluing jig such as the one cataloged by Micro-Mark. This will help square things up and hold them in place while the glue is drying.

Scratchbuilding the Roof

The roof for your model building can be made out of cardstock or mat board as well as styrene, and then covered with an appropriate vinyl or plastic roof sheeting material that you can purchase (from Plastruct, et al.); or you can make your own shingles. There are lots of different ways to make roofing shingles. The following method may be one of the easier ways of roofing your structure. You can probably even devise your own method later, but this will get you started.

To make shingles…

• Buy some pinking shears at your local craft store that will give you the kind of pattern that you want for your shingle edges.

• You will also need gummed (contains adhesive that has to be moistened) kraft paper, which tends to stick to cardstock or matboard better than it does to styrene. If you’ve used styrene for the roof, you may have to use regular glue to get the paper to stick better.

• With a pencil and straight edge, draw parallel horizontal lines on the subroof.

• Then cut the gummed paper with the pinking shears into strips – a little wider than the space between the lines you drew on the roof.

• To begin the shingling process, glue a plain strip of gummed paper with a straight cut along the bottom of the roof. (The glue on the paper is activated by moisture, as mentioned above.)

• Then, along the next parallel line glue a notched strip; glue another strip above that, and continue this till you get to the top. Stagger each new strip by 1/2 cut to the right or left to create a diamond-like pattern on the roof.

• Then do the other side of the roof the same way.

• You may need to do some trimming later with a sharp hobby knife (wear safety glasses), but wait until it’s all dry first. The paper won't cut very well and may tear if you try to cut it while it's wet.

• You can then paint it and weather it, as you like.

Details

Don't forget to add details like chimneys, roof vents, eaves, awnings, flower boxes, window air conditioners, gutters and downspouts, trash cans, lamps, decals, people and pets, etc. The details are what make your model buildings come alive. Most or all of these items can be found in the Walthers catalog. Or, again, you can make your own.

Interiors

Also you may want to add some detail to the interior of your model, especially for HO, S and O scale, but even for N if you can fit them in. This is covered in the Model Railroad Buildings page.

Contests

If you are scratchbuilding a model that will be judged in a contest, such as in structure-modeling to achieve points for the NMRA Master Model Railroad program, the more details you can make yourself, the more points you will get. For example, after you have constructed the styrene walls, you may want to add strips of wood on the outside to create wood-siding. You can make a mural stone wall by cutting embossed thick cards and gluing each piece on the wall to create the desired look. Make your own decals from magazine pictures. Make your own awnings from cloth and toothpicks, etc. The less you purchase and the more details you add yourself using simple materials, the better you will do in acquiring points. I would also recommend light weathering for your finished model.

References

Laser Cutting for ScratchBuilding Projects, by R.J. DiMaggio - Many model railroaders like to design their own buildings on computer and then use a laser cutting service to create the parts according to their specifications. Here's how it works.

Scratchbuilding for Model Railroaders: Craftsman Techniques Made Simple

Ipswich Hobbies - Model Railroad Craftsman Kit Structures - Ipswich Hobbies is a small company that focuses on delivering laser cut craftsman building kits that are based upon prototype structures. Kits are also available pre-built.

Textures.com - a great place to find materials for scratch-building structures

Keep an eye on the railroad forums (listed on the "Comments" page) periodically to look for postings of lots of different ideas, projects and new methods of model building written by true model railroad craftsmen.

A project like this can be a little intimidating when you start, but if you break it down into small projects, each of which would only take a short amount of time. Then, if you just do one of those little projects each day, you will be amazed by your progress after just a few days. After finishing your model, you will also be amazed about the amount of satisfaction and pride you will feel from having completed the model and, even more so, after putting it on display - either on your layout or at the model railroad convention.

*This page was updated on July 15, 2020.*

From "Model Buildings from Scratch" to Model Railroad Buildings"

From "Model Buildings from Scratch" to "Homepage"

Contact Me | Blog | Photos | References | Supplies | GiftShop | Sitemap | Search | Comment | Privacy Statement | Disclosures

Tracks Newsletter: Sign Up Here!

√ = ad or sponsored link

What's New on BYMRR.com?

Recent Articles

-

Model Railroad Supplies

Dec 16, 25 03:46 PM

We have started a new store to help you build your layout and teach your youngsters about science with STEM products. -

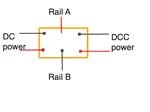

DC and/or DCC on the Same Layout

Mar 09, 25 10:46 AM

How to wire your layout for either DC and/or DCC operation. -

Looking for a locomotive speaker

Nov 24, 24 07:29 AM

First Name: Randy E-Mail Address: bymrr@building-your-model-railroad.com Enter your question: : I am looking for a speaker for a Walthers EMD SD70ACE Locomotive, product number 910-9866. The control b…