|

Model Railroad Operation: A New Adventure!

Model railroad operation is a very important and exciting aspect of model railroading that, for many model railroaders, serves as the main goal in the hobby. In fact, many feel that before you even start building your layout, the planning should incorporate how the railroad will be operated, how trains will move, how trains will be assembled, where the staging yards will be located, etc. This should simulate as closely as possible how those who have a real job on the railroad would do it.

Planning for Model Railroad Operation

There are several elements of track planning to consider when deciding about model railroad operation for your layout…

• Will portions of your industries be online or offline? For example, you could have a sawmill in one area and a furniture warehouse that obtains wood from the sawmill in another area, but you don’t have to have both. You could just have the sawmill where trains load up with wood then travel to an offline staging yard where the trains become empty again, presumably because they’ve gone to a customer where the lumber has been unloaded.

• Will your staging yard be hidden? Most of the time it will be hidden behind a mountain, elevated scenery, or even in an adjoining room. Some layouts have staging yards underneath the main layout, or above the main layout accessible by a helix. They don’t have to be hidden, however, if you use it as an interchange between two main rail systems on your layout.

• How long do the tracks in the staging yard need to be? This depends on how long you want you average train to be and how much space you have available. Stub tracks are able to be longer than tracks connected to a ladder on each end. You may want to have both.

• How many tracks do you need in your staging area to provide for optimum model railroad operation? You usually need about twice as many as you think you need, and after you’ve built the yard, you always need more than you have. The minimum should be the number of trains you have plus at least two more for arriving and departing trains. If your tracks are long enough, you could potentially double-up and have two trains on one staging track, but the operation and flow are probably better if each train has it’s own track.

• Should your staging yard have any loops so that trains can be turned easily? This would work well for passenger trains that don’t have to appear loaded or unloaded when they re-appear on the layout. Freight trains, however, when they go into staging usually are changed from loaded to unloaded or vice versa. It doesn’t make sense for your loaded coal train to go out of the layout from the coal mine, and then return to the coal mine later still fully loaded. So you will have to do some switching while the train is in the staging yard, before the next session. You could have stub tracks for freight and flyover loops for passenger trains. You could also have ladders on both ends of the staging yard for entry into the layout from either end.

• If your staging yard is completely hidden or difficult to see during a model railroad operation session, you will need to install detectors, or sensors, in the staging tracks so you will be able to tell where your trains are on a control panel on the fascia or at the dispatcher’s desk. That way, you will know when you've backed the train in far enough.

The Process of Model Railroad Operation

Moving railcars to and from their industries, customers and staging yards is the main goal of model railroad operation; and it should be done in a way that is at least somewhat prototypical and makes the most sense. There are several ways that model railroaders have devised over the years to accomplish the tasks of moving cars. Two of these methods are described as follows…

Switchlists are a very prototypical method of moving rail cars in model railroad operations, since this is what the real railroads used. Basically, the yardmaster lists all the cars on his switchlist, and then, next to each car, depending on its destination, he places a number for the track in the yard that it’s supposed to go to - so that it can be placed in a consist with other cars going in that same direction or to that same location. Furthermore, the cars can be lined up in order corresponding to where they will be dropped off. You could use numbers of mileposts to help with sorting, such that cars going to milepost 74 would be closer to the engine (and the last to be dropped off) than the one going to milepost 52. Further back, would be the car going to milepost 19, which would then be the first of the 3 cars to be dropped off.

Using car cards and waybills is probably the most popular method of car forwarding used for model railroad operations. You can buy the forms for this through Micro-Mark or Old Line Graphics; or you can make your own. Basically, each rail car has an associated car card containing a pocket that holds the smaller waybill, which tells where the car is going. You can make up the waybill so that it can be used for 4 operating cycles or sessions and just turn the card upside down and/or front to back to use the different cycles at different operating sessions. That way you, the host, only have to set up the cards and waybills once to use them for 4 different sessions, and then use them over again starting with cycle 1. This provides variety for each session. By the time you get back to cycle 1 everyone has forgotten about it.

The car cards contain the road name, like PRR for Pennsylvania RR, the type of car, like coal car, and the number of the car that you can find written on the side of the car.

The waybills contain the routing information for the car, like which railroad lines it will be traveling along (e.g., B&O, PRR, C&O, WM), the name of the shipper and the name of the receiver, for each cycle.

The yardmaster’s job in a model railroad operation session, then, is to arrange the cars according to where they’re going and the order in which they will be set out, or dropped off – in other words, make up the consist for each train. When the train is ready, it can be placed on a departing track; and when the yardmaster receives clearance from the dispatcher, the train can be pulled out by a crewmember and taken to its destination, dropping off cars at various industries along the way.

All of this activity is often done according to schedules and timetables set up by the host or by the chief dispatcher to hopefully provide for smooth model railroad operation. The typical operating session is run based on a fast-clock, which compresses a 24 hour train schedule into 3-4 hours, depending on how long you want your operating sessions to last. The operating crewmembers must try to keep their trains on schedule as much as possible. The trains are expected to arrive and depart at certain times to be sure the goods are picked up and delivered on time. Otherwise the shipping and receiving “customers” of the railroad will be unhappy and may start using a trucking service instead (not good for the railroad company). This requires a lot of teamwork as you might expect and a little time pressure to get the jobs done, but that’s all part of the fun.

For more information and a great example of realistic model railroad operation, see the page on Chuck Davis' Lehigh Valley RR.

Types of Trains and How They Move

From the model railroad operation perspective, there are many different types of trains that have different purposes and move in different ways…

• Local freights (also called way freights, peddlers and other names) - These do most of the pick-ups and drop-offs (set-outs). It usually stops at every town and leaves some cars and picks up others. It is usually subservient to passenger trains, fast freight and through freight trains, which basically means if one of them is coming, the local has to get out of the way.

• Through freights usually travel from one yard to another, dropping off some cars (“propers”) at one yard and carrying “throughs” on to the next yard or destination. “Hot cars” may be positioned on the head end for quick removal, and usually contain perishables or other important items like auto parts.

• Fast freights usually contain only a few blocks of cars, pre-arranged at the origination point, that are moved to their destinations as soon as possible without being tied up in yard switching any more than absolutely necessary. That way, they can adhere to a much faster timetable than the other freights. This would be good for fruits and other perishables. If a fast freight arrives in your yard, you want to try to do everything possible to get them on their way as quickly as you can.

• Turn - This is a freight train that goes out from a yard to a certain destination, then directly returns back to its origin.

• Symbol freights - These are usually fast freights that have a fancy name used by the railroad company in marketing. It sounds better to railroad customers if their goods are being shipped on a train called the Blue Streak, rather than just any old freight.

• Mine Runs(also called shifters) - Local freights that serve mine branches, exchanging empties for loaded cars, also carrying LCL (less-than-carload-lot) mine supplies and other freight occasionally.

• Passenger trains - Many of these have had fancy names as marketing gimmicks. They usually lost money for the railroad, but were used as marketing tools for the more profitable freight business. There were also local passenger lines, similar to local freights, that stopped in every town. Short lines were famous for operating mixed passenger and freight trains.

• Extras - These are trains, either freight or passenger, that are not listed on the timetable, but are required for extra work. In these situations, the lead locomotive is required to carry a white flag or have classification lights, to let other trains know its status. A scheduled train may also have additional sections running behind it carrying green flags (all but the last section).

You may have 2 or more different types of the above trains involved in model railroad operation on your layout. How these are all orchestrated to move from one place to another to get their work done is the job of the chief dispatcher - a position that may require a little experience by working on smaller railroads, or by working as an apprentice on larger railroads, before moving into the position on a regular basis.

Trying to figure out which one of your crew is suited for which particular job on the railroad may be somewhat challenging for the host. It’s probably a good idea to move people around on different jobs at different sessions, so that no one gets bored doing the same thing over and over. Some folks will never want to be a dispatcher or yardmaster. Others won’t want to leave the dispatcher’s chair or yardmaster’s position once they’re in it. Newcomers will have to start slow to get the hang of it. You may want to limit the number of newcomers to each session, so you don’t get too bogged down in orientation. You should always try to make sure everyone has a job. If not, some members may need to come to alternate sessions, or you may just have to limit the number of members. You want your operating sessions to be lively, interesting, socially inviting and friendly - never boring, and always fun!

References on Model Railroad Operations

Realistic Model Railroad Operation, by Tony Koester, 2003, Kalmbach Publishing.

Realistic Model Railroad Operation: How to Run Your Trains Like the Real Thing (Model Railroader Books)

Also see You-Tube Videos that help explain model railroad switching operations in great detail.

| Helpers

-An additional TIP on model railroad operation-

In the April, 2009 issue of Model Railroader, on p.114, Andy Sperandeo wrote a very informative one-page article on "Helper Operations", in which he talked about the various prototypical ways in which helper engines can be used to get your trains up steep grades. Double-heading is the simplest of these and of course involves adding an extra 1 or more engines at the front of the train to help pull the train up the grade. This is fine if the train is in a straight line, but if the grade involves going around a curve, you end up with a problem called "stringlining", where the cars in the middle are pulled back by the weight of the train and pulled forward by the engines and end up being forced off the track. In that case, you may need to use pusher engines at the rear or in the middle of the train to prevent this. Pushing against a caboose may be okay if it has a steel frame, but many do not prototypically and you don't want to put your crew in danger, so you may have to do some switching to get the caboose off then back on again after the climb is finished. You can also use a pusher with the coupler locked open, so that when the grade climb is finished the train simply pulls forward and the pusher falls back without requiring an uncoupling procedure. The pusher then goes back down the grade to return to its base. Check out the article for more details!

|

From "Model Railroad Operation" to "Homepage"

From "Model Railraod Operation" to "Special FX" page

Contact Me | Blog | Photos | References | Supplies | GiftShop | Sitemap | Search | Comment

Contact Me | Blog | Photos | References | Supplies | GiftShop | Sitemap | Search | Comment | Privacy Statement | Disclosures

Tracks Newsletter: Sign Up Here!

√ = ad or sponsored link

What's New on BYMRR.com?

Recent Articles

-

Model Railroad Supplies

Dec 16, 25 03:46 PM

We have started a new store to help you build your layout and teach your youngsters about science with STEM products. -

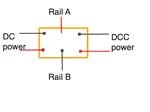

DC and/or DCC on the Same Layout

Mar 09, 25 10:46 AM

How to wire your layout for either DC and/or DCC operation. -

Looking for a locomotive speaker

Nov 24, 24 07:29 AM

First Name: Randy E-Mail Address: bymrr@building-your-model-railroad.com Enter your question: : I am looking for a speaker for a Walthers EMD SD70ACE Locomotive, product number 910-9866. The control b…