|

Model Railroading Questions

and Answers

Since 2009 when this website was started, we have been answering questions by email from model railroaders all over the world. After answering one of these recently, I thought it might be prudent to have a page dedicated to those questions and answers that might be helpful to others as well. If you have a question that you would like to send in, please enter it in the box below and we'll do our best to answer it.

(Disclaimer: We don't know everything, but we'll give it a good try. If we don't know, we'll try to find someone who does.)

We may use your first name in our answer, but your email will not be published, sold or used for any other purpose than responding to your question. (Privacy Policy)

What Track To Use?

Q - "Which track is the best to use?

Hornby, Peko, others?

Can you use different brands together on the same layout? or best to stick to one?"

A - I don’t think the brand of track you use matters that much. It's how carefully you lay the track that matters the most. I would try to use the same brand throughout your layout - for appearance sake if for no other reason. Turnouts should be the same brand also. I’ve used mostly Atlas. I’ve also used Bachmann, Life-Like, Arnold, Kato. If you need curved turnouts, I would use Peko due to greater availability. I like to use a lot of flex track, which reduces the number of rail joints and is good to use if you don’t have the right-sized sectional pieces.

You can use different brands on the same layout and I have done that successfully. Just be sure it is all the same code (height of the rail) on the mainline. You may use smaller code track on branch lines. The prototypes do that frequently. Just be sure that when you lay different codes of track next to each other, the rails are flush at the top of the rail.

Whatever brand you use, I would be sure it is nickel silver and not brass which requires more frequent cleaning.

Track-work precision in the beginning is very important to the future enjoyment of the hobby. If you have a lot of derailments, it won’t be as much fun. Also after many years of operation, even the best-laid tracks require troubleshooting due to expansion, contraction and tiny shifts in position.

Check out the pages on Laying Track, Track Planning, and Layout Design on the Building Your Model Railroad site.

Joe Fugate's book on Trackwork may also be helpful to you at this point.

Why Styrofoam?

"Do i really need Styrofoam on top of my plywood layout, and if so why?”

It’s a great question! The quick answer is No, you don’t really have to use Styrofoam on top of your plywood. There are certainly other ways to build your layout surface. You could just use the plywood itself and tack or glue the track to it, which is what I did in the beginning. You can build your terrain on top of that. You can even use the "cookie cutting” method using a jigsaw to create elevations of your track. There is also the wood splicing method of creating pathways for your track, which I think is difficult and time consuming if you’re not a carpenter.

Sometimes if you tack the track directly to the plywood surface, when you run trains , they make a sound that isn’t very realistic. That can be helped by using cork or foam roadbed under your tracks. Some modelers like to put a sheet of Homasote on the layout surface and lay tracks on top of that. Homasote can be cut with a saw, but it makes a mess.

There are advantages and disadvantages to all these methods, and it is certainly not wrong to use any of them. Many great modelers have used those options. I personally like the Styrofoam sheets that are typically used as insulation for home construction…

Advantages:

- Quiet surface to run trains

- Easy to work with. You can cut it with a hobby knife or hot knife.

- You can bury wires in it.

- You don’t have to crawl under the layout to do your wiring.

- You can bury circuit boards in it.

- Easy to make ditches along the sides of your track.

- Easy to create valleys, creeks, rivers, ponds by cutting into the Styrofoam. Much harder to do that with plywood.

- Easy to create tunnels, mountains covered with plaster-cloth, track elevations, etc.

Disadvantages:

- If you like to use under-the-layout tortoise switch machines, you either have to use long rods to get from the bottom of the layout to the layout surface to reach the turnout, or bury the Tortoise under the track in the Styrofoam. (That’s not that difficult because the Styrofoam is easy to cut and you can place a flat piece of balsa wood over it to provide a surface for your turnout.)

- There may be other disadvantages, but I just can’t think of any right now.

Question about Derailments:

i’m hoping you can help me with a problem i’ve been experiencing with derailments.

about six months ago i got a kato santa fe n-scale super-chief 8-car set pulled by a santa fe warbonnet locomotive. i run it on a loop mounted on the walls of my 11’-8” x 14’-4” den about 6” below the 10’ ceiling.

the train ran flawlessly for months, but only in one direction. when i tried to run the set in the opposite direction there were endless derailments and uncouplings. so i no longer attempt to run the train in the opposite direction. recently i’ve been experiencing frequent derailments of one or more of the cars. i traced the problem to a minute gap in one of the rail sections. running my finger over this gap i can detect a slight but noticeable height difference across the gap in the outside rail only. i believe this is causing the wheels to bounce which results in the derailment a few feet down the track.

i plan to eliminate this anomaly using a fine-tooth file from a hardware store or home depot. do you think this is a good idea? and, if so, do you think the hardware store file is the appropriate tool for this purpose or do you think i should purchase a more specialized file from a model train dealer or hobby shop?

also, i have two re-railer track sections incorporated into the layout. can you explain why these re-railers never automatically re-rail the cars?

tnx.

Answer:

Derailment problems are quite frustrating at times, and yours may be even more difficult because of the difficulty in visualizing the track. A 6” space isn’t room enough to get your head in above the track to really see what’s going on. You might consider using a small camera to try to capture the derailment, then play the video back slowly to try to see what happens at each point of derailment. If you don’t have a small camera to use, try using a small mirror.

Correct rail height irregularities:

I agree with your plan to use a file to try to reduce the rail height at the point where it is uneven. A regular metal file will do, but be sure to vacuum and/or wipe up any tiny metal shavings that come off the track. A magnet might help the effort. These can get into your locomotive engine and potentially ruin it over time. There may be more gaps that you can’t feel, that maybe a small mirror or video camera would pick up. Rails tend to expand, contract and sometimes even buckle with changes in heat and humidity with the different seasons. (See the paragraph below regarding the use of the NMRA gauge to determine if the rail distance is proper.)

Curves:

If your curves are too tight in the corners, that could be a problem, especially if the wheels on your cars are not running smoothly, or if your cars aren’t weighted properly. If you have any S-curves, make sure there is at least one full railcar length of straight track between the 2 curves of the “S”.

Clean everything

Make sure your track and all the wheels are clean. Dirt and dust can accumulate and cause problems. That may be why your rerailers aren’t doing their job. I like to use “GooGone" for cleaning track.

Metal Wheels:

If you haven’t already done so, you may want to change all your railcar wheels to metal ones. They seem to roll more freely and “hold" the track better than plastic ones. Make sure there is not too much horizontal “play” where the wheels fit into the trucks.

Check standards:

While you’re doing that, check the coupler height gauge using an NMRA N-scale gauge checker that you can buy inexpensively from their website at NMRA.org. If the couplers are not all the same height, it will lead to uncoupling occurring when you don’t want it, especially when pushing the train backwards.

Also while you’ve got the railcars on your work table, check the weight of each car and make sure that it meets NMRA standards based on the length of each car, which are listed on the site. A small inexpensive food-scale will do. If your cars are not heavy enough, it will be easier for them to bounce off the track if they hit any irregularity. You can buy small metal weights for this purpose, but you can just use old fishing weights or any other small metal object glued to the inside bottom of the railcar.

For N scale, you would take the length of the car in inches, multiply by 0.15, then add 0.5 ounce to that to get the optimum weight in ounces. If your car is underweight, add small weights one at a time to the inside of the car on the bottom till you get it to the proper weight. Then glue the weights down.

Your NMRA gauge can also help determine if the distance between the rails have come together or widened too much with the changes in the temperature and humidity. Again you will have to use a camera or a mirror so you can see the results. The only remedy I can think of for that is to replace that section of track.

Turnouts:

If you have any turnouts, make sure the points are flat up against the rail on each side before and after the switch is thrown, and that they are working properly. Again dust and grime can affect their performance greatly.

Reverse Operation:

“Pushing" the train backwards, will always increase the risk of derailments, especially if any the above problems are present. The most likely problem here is that there is too much resistance to the prefered easy flow of the railcars where the wheels meet the rail, especially in the back of the train. You need to reduce that resistance as much as possible by cleaning the wheels, including the “holes” in the trucks where the axels sit, replace the wheels with metal ones if necessary, and make sure the railcars, especially in the center of the train are weighted properly. If you have light cars in the middle of the train and heavier cars in the back, when you back up around a curve, the middle cars will come off the track because they are being pushed from both ends.

Graphite:

After cleaning the wheels and track, if they still don’t seem to be running smoothly, try applying some graphite from a pencil to the point of each axel. You can also buy some lubricant to use for that, or even use some transmission fluid on the end of a toothpick. Also, a tiny amount of transmission fluid applied to the track with a non-shedding cloth helps to reduce friction and improve rail conductivity.

All of that may seem like a lot of work, but if you take your time, and don’t try to do it all at one sitting, I think you will be rewarded with a better-running train. I don’t think it would cost much, except for a small investment in metal wheels, a small inexpensive scale, metal weights, a pencil and an NMRA N-scale gauge.

Question about Benchwork:

Q: I’m getting back into railroading and have a question about plywood size. Is it ok to use 4x4 pieces instead of 4x8 sheets? I don’t have a truck and wondered if that would work for the bench work and butt them together. Thanks, Tim

Answer:

Absolutely. In fact I have done that same thing. I used Woodland Scenics Mod-U-Rail benchwork for my current layout, which was easy to put together and doesn’t really require any carpentry expertise. I then asked my local home improvement store to cut 4 pieces of 4’x4’ and 3 pieces of 2’x4’ 3/4” plywood to use as the surface of my layout. I used 3 of the 4’x4’ pieces in the corners and one to make a small peninsula. I cut off the corners of the 4'x4' pieces so the sharp corners wouldn't stick out into the aisles. I then used the 2’x4’ pieces in between the 4’x4’ pieces to line the walls. I used long wood screws to fasten the plywood to the benchwork to hold it in place. Wherever one piece of plywood was not flush with the one next to it, I used a 6” section of a 2”x4” board and screwed it in to each piece of plywood from the bottom where they butted up against each other. Not only was this easy to do, but it also makes the layout easier to dismantle and somewhat portable in case we ever have to move.

Pennsylvania Railroad Steam Engine Class K4. This picture was taken in Aberdeen, MD on April 26, 1944. (Courtesy, Wikipedia)

Pennsylvania Railroad Steam Engine Class K4. This picture was taken in Aberdeen, MD on April 26, 1944. (Courtesy, Wikipedia)Question about Pennsylvania Railroad:

Q: New to model trains. What train is the K-line 1107 Pennsylvania iron horse designed after? Want to make a scene that matches the era of this model train.

Answer:

The Pennsylvania RR K-Line refers to the Class K-4s of locomotives (4-6-2 “Pacific”) produced by the Juanita Shops in Altoona, PA starting in 1914 with the fleet number 1737 and ending in 1928 with a total production of 425 locomotives. I was not able to find a specific reference for the 1107, but it was most likely made, or based on, the steam engines produced in 1917 or 1918, since the numbers used after that were all higher than 3726. It’s possible that the “1107” is a fictional number made up by Lionel, not based on any particular locomotive.

The original K-4s was inspired by the K29s that Pacific built in 1911 by the American Locomotive Company (ALCO) and by the design used for the E6 4-4-2 “Atlantics”. They hauled the majority of express passenger trains for PRR until they were replaced by diesels and electrics. The K4s were used for heavier trains in the 1930s but they required double or triple-headers in order to do so.

The K4 is recognized as the State Steam Locomotive of Pennsylvania. There are only 2 survivors, 1361 and 3750.

Ref: Pennsylvania Railroad class K-4s, Wickipedia, American-Rails.com/k-4s

Question about Turnouts:

Q: Could you tell me please, what does the term "6th radius" mean, or where may I find a clear definition of it?

Answer:

The 6th radius is a designation used by the Peco brand of turnouts (designated as a #6 turnout by other brands) referring indirectly to the radius of the turnout, but more directly to the ratio of the distance between the angle of the frog to the point where the diverging tracks have a width that is 1/6 of that length. The number 6 is not a measurement but a ratio, which has been used to refer to that type of turnout. The 4th radius turnout, or a #4 turnout, as usually designated by other brands, would have a smaller radius than a #6 turnout. A #8 turnout would have a larger radius and provides for smoother operation if you have the space for it, because the higher the number, the longer the turnout has to be. The following article by the NMRA may help clear this up for you...

https://documentcloud.adobe.com/link/track?uri=urn:aaid:scds:US:ac68e225-72fa-4438-aab4-dfa5bdb6b345

MRC Tech 6 Power Pack and Sound Controller for DC Model Railroad Layouts

MRC Tech 6 Power Pack and Sound Controller for DC Model Railroad LayoutsQuestion about How to Get Sound on DC Layouts:

Q: If I have an analog layout If I buy a n scale loco with onboard sound will the sound work on the track?

Answer:

The answer is YES, but you will have to purchase a special DC transformer that has this capability.

It is made by Model Rectifier Corp, called MRC Tech 6. It can operate DCC sound-decoder equipped locomotives on analog track with all the usual DCC functions including the ability to change CVs and programming of the decoders.

Here is a video explaining its capabilities.

Another option would be to just switch over to DCC with a Digitrax Zephyr or NCE starter system. These can operate both DC (using “00” as the code) and DCC locomotives.

Layout Surface: Foam Pad or Plywood?

Q: I am planning a 4X6ft. N scale RR. I plan to use a 4X6ft. piece of plywood. I want to nail the track to a cork sub roadbed. What advantage does foam have? Thanks.

A: The main reason I like to use foam pads as a layout surface

is that if you want to dig out a creek, a lake or a ravine, it is much easier

to do that if the surface is foam rather than plywood. It’s also helpful if you

want to put a magnet under your track to use for uncoupling. A third reason is

that it is easier to manage wiring. You can run wires easily through the middle

of a foam pad to the side of your layout where your turnout switches or control

panel might be located, or to run wires for an new light fixture that you want

to put in the middle of your layout. Fourth, you can more easily embed a

structure into foam so that you don’t have the foundation of your structure

hovering over the surface of the layout. It’s also easier to plant trees in

foam than in plywood. Foam is quieter than plywood when running trains. I also

think that nailing the track down to plywood doesn’t allow for expansion and/or

contraction of the track as the temperature and humidity change throughout the

different seasons. So after a few years, you might find your track buckling a

little.

You still need the plywood under the foam pad for a good, steady layout surface, but for all the reasons above, I like foam pads on the top.

How to Wire a Reversing Loop to Accommodate Long Trains Containing Lighted Cars

Q: Generally, a reversing section needs to be as long as the longest train that includes lighted cars to prevent shorts due to polarity issues. A question came in from Rick asking how to deal with this without having to shorten your trains or change your track plan. I sent his question to an electronics expert, and here was his response:

"The problem with reversing loops is that at one end of the loop or section, the adjoining rails will be of opposite polarity, separated by an insulating rail joiner, or on my layout by an open gap. When a metal wheel bridges this gap there is a short circuit and the booster will shut down. If all your rolling stock has plastic wheels, you only have to worry about the motive power and the actual reversing section can be quite short, but it only takes one metal wheel on a car to cause a problem. Since I run petty long trains with all metal wheels, I came up with my own solution that I described in the Auto Reverse Section article.”

https://documentcloud.adobe.com/link/track?uri=urn:aaid:scds:US:27b02eaa-10d7-4a90-98a0-c334bd7c01fb

This looks complicated because he put a lot of detail into this article, but once you study it a bit, you will get the idea. Pay particular attention to the blue and green schematic and the highlighted text which basically tells you how it works when your locomotive approaches the loop from either direction.

To do this you will need to purchase a 4PDT Relay, four Hall effect switches and some 6mm x 1.5mm magnets. Follow the directions carefully about where to put rail-gaps and how long those sections of track need to be. Wire it up according to the blue and green schematic and it should work well no matter how long your trains are, lighted cars and all.

Back to Home Page

Contact Me | Blog | Photos | References | Supplies | GiftShop | Sitemap | Search | Comment | Privacy Statement | Disclosures

Tracks Newsletter: Sign Up Here!

√ = ad or sponsored link

What's New on BYMRR.com?

Recent Articles

-

Model Railroad Supplies

Dec 16, 25 03:46 PM

We have started a new store to help you build your layout and teach your youngsters about science with STEM products. -

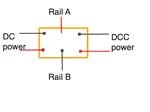

DC and/or DCC on the Same Layout

Mar 09, 25 10:46 AM

How to wire your layout for either DC and/or DCC operation. -

Looking for a locomotive speaker

Nov 24, 24 07:29 AM

First Name: Randy E-Mail Address: bymrr@building-your-model-railroad.com Enter your question: : I am looking for a speaker for a Walthers EMD SD70ACE Locomotive, product number 910-9866. The control b…