|

Troubleshooting

Your Model Railroad

One thing is for sure about this hobby:

Troubleshooting your model railroad is as much a part of model railroading as is building the layout in the first place. Like most things, the more moving parts you have and the more complicated your wiring is, the more likely things will go wrong eventually.

If you want a problem-free layout, keep it small and very simple, and it will be boring. Conversely, if you want a layout that is fun and exciting to operate, you should expect to have a problem or two along the way.

Keep in mind while building your layout that the more meticulous you are with your wiring and track-work especially, the fewer problems you will have later. You may be tempted to cut corners since you are in a hurry to get your trains running, but it's very important to be patient and do each job correctly before moving on to the next one. It is easy to say to yourself that what you've done is "good enough for now, I'll make it better later". What happens is that you never get "back to it later" and it ends up becoming a problem later, usually when you're showing your trains to someone or during an operating session. And it often requires more time to fix it afterwards than if you had done the job correctly the first time. Don't rush through the layout building process. Relax and try to enjoy the journey.

Also, keep in mind that the older your layout is, the more likely you will have problems due to corrosion, climate-related expansion and contraction of metal parts, dust and dirt interfering with your equipment, vibrations causing wires to loosen over time, lights burning out, warping of plastic or wood, just to name a few.

So, I thought it might be helpful to have a page dedicated to troubleshooting your model railroad, particularly with regard to some of the most common problems that are likely to occur. Since I have written some of these same tips in other parts of this site, and rather than re-writing them all here, I will discuss some of these problems in generalities and provide links to the more detailed information.

Troubleshooting Your Model Railroad Wiring

Use wire connectors, avoid stray strands: I like to use solid copper wires rather than stranded, since it is less likely for those little strands to stray over to a terminal connector where you don't want it to be. Also, they are easier to solder. Stranded wires are more flexible though and are less likely to break. If you use them, crimp a connector over the strands so they are less likely to stray.

Label your wires: As you begin wiring your layout, you will quickly discover that you MUST keep your wires organized. Use colors and labels so you can easily see which wire goes to what. One way is to organize them according to whether they go to lights, tracks, turnouts, or other accessories. Get an inexpensive labeling device to help make labels quickly on the fly.

Power distributors with circuit breakers: If you have a room sized layout, separate the power to your layout into four power blocks and connect each block to its own power distributor containing a circuit breaker, such as Digitrax PM42 Quad Power Manager with auto-reverse. With power distributed to four quadrants, if a short circuit occurs in one quadrant, it shuts down the power to that quadrant only and the rest of the layout is still operational. Also, it makes it easier to locate the problem.

Loss of power: If you lose power to your entire layout, that's probably due to a circuit breaker or a blown fuse in your home or building where you operate your railroad. If you continually have to reset the circuit breaker, you have too much of a power draw in your system that is running through that circuit breaker. If you have other things (not your layout) connected to that circuit breaker, like the laundry machines, etc., you may need an electrician to help you separate the other power grabbing items that are connected to that breaker or fuse. If you lose power to only one section of your layout and if you have power distributors, that significantly narrows the problem down to a short circuit in that particular area. It could be just a simple problem such as a locomotive sitting incorrectly on a turnout. Look for the simple problems first before you go about rewiring the whole area.

Electronics: Sometimes electronic devices go bad or are defective. This can happen with any brand. So, if you have an interruption in power and you believe the wiring is all good, consider replacing the transformer or power unit. Make sure it is plugged in (Don't laugh!). Make sure the receptacle where it is plugged in has not gone bad. Check that your surge protector is turned on. Try removing the last electronic device that you added to the layout and see if the problem is solved. If so, then the device is defective. Get an electrically-savvy friend to help you figure it out.

Soldering: Practice soldering before hand in order to do it well on your layout. Follow directions carefully when soldering wires to devices or to circuit boards. If a stray bit of solder makes an unwanted connection, there may be a short circuit.

Signals and Crossing Flashers: Wiring signals for automatic operation can be a bit complicated. Follow the directions and/or wiring diagrams very carefully. Be careful not to use a signal device that is made for DC (direct current) operation on a DCC layout which is AC powered. The signal lights will burn out and the device will be useless after that.

Lights: LED lights must have a resistor attached to the common lead and must be lined up in the circuit with the proper polarity. In this case direction matters. When using grain-of-wheat bulbs, these can be hooked up to either AC or DC and it does not matter which direction. Grain-of-wheat bulbs may have to be replaced now and then. It is helpful to have removable roofs on buildings to make it easier to replace bulbs when you need to do so.

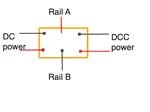

DCC Problems: Do not combine DCC (AC current) devices with DC current track or vice versa. If you want to have a layout with both DCC and DC locomotives, they must be on two separate mainlines. Some people try to run DC locomotives on DCC track using the code 00 in their DCC command station. You may get away with that for a while, but you run the risk of burning out your locomotive motor.

Troubleshooting Your Model Railroad Tracks

Track-work: Laying your track correctly and flawlessly is probably the most important thing you can do to avoid problems later. Take your time when doing this. Test and retest, and then test again. Don't put any scenery down until you are sure the track is perfect. Be careful about S-curves. You must have a perfectly straight section of track for at least one full car length of your longest car in between the two ends of the S. Same with parallel curves. Make sure they are far enough apart that your longest cars can travel on those separate tracks without scraping against each other. Again, you must test and retest with different cars.

Track codes: Track code refers to the height of the rails. The higher track codes are generally used for heavier traffic and heavier loads. You may choose to use code 100 for your mainline and code 83 for branchlines. Prototypes often do this. The problem is that when you connect code 100 track to code 83 track, there will be a difference in the height of the adjoining tracks, which is a place where a derailment may occur. When you connect these tracks, you must place a shimmy (usually a thin flat piece of wood) to elevate the code 83 track so that the top of its rails are flush with the rails of the code 100 track. Then you must either glue the tracks down so they stay that way, or solder them together. The tops and the insides of the rails should be flush with each other as much as possible.

Turnouts: A lot of derailments occur around turnouts, so you will want to be careful that you lay them correctly and that you test them repeatedly backwards and forwards before you move on to the next project. Wiring remote turnouts can be simple or complicated depending on the brand and whether you want them to be automated. That is the subject of an entirely different article for which there is not enough space in this format. There are videos on YouTube that help to explain this better than I can here. For unwired turnouts, you need an NMRA gauge to check on the space between the rails to be sure it meets NMRA specifications, which sometimes they don't, even right out of the box. If your railcars bounce and derail as they go over a turnout, put a small mirror on the track and try to locate exactly where that is happening. Frequently the plastic insulator in the frog of the turnout is too high and the car bounces over it when it hits it. If this is the case, take a thin file and file down the plastic slightly until it is even with the rails. If you file it down too far, there will be a dip, which is just as bad. Continue to test and retest cars running over the turnout at different speeds and with the points open and closed. Use a variety of different railcars and locomotives that you will be running on your layout. File the turnout anywhere there is a hangup. If you can't get cars or locomotives to run smoothly over the turnout, replace it now before laying any more track. It is much easier to do it now than later after all the track has been glued down, and the ballast and scenery have been added. Remember to vacuum up any filings you've created so they don't end up inside any locomotive gears.

Inclines: Grades should never be greater than 4%. Otherwise you will have locomotives than won't be able to pull more than 1 or 2 cars behind them, and they will move too slowly, stall, or the wheels will start slipping. You can try to fix that by adding 1 or 2 more locomotives to the consist, but that often just results in more slippage and usually doesn't work. When you are first building the incline, I would err on the side of keeping inclines less than or equal to 3% for better operation. If your incline is already built and is too steep, you will likely have no option other than to redo it.

Stalling locomotives: This often occurs over a rail gap or across an insulated frog of a turnout, where there is an interruption in the power to the locomotive. You can fix this by added another locomotive behind it to push it through the gap or by adding a "stay-alive" capacitor to the wiring inside the locomotive.

Jerky locomotives: This is usually caused by dirty tracks or dirty wheels. The problem is easily solved by cleaning both the tracks and the wheels. Another possibility is that the locomotive gears or axels need to be lubricated with some 108 Labelle Oil, especially if it's an older locomotive that has been sitting on the shelf for a year or more. A third possibility is there may be a loose pick up wire inside the loco.

Derailments: This usually occurs because of track work or turnouts either not laid well to begin with, or the tracks have contracted and re-expanded multiple times through the different seasons such that the alignment has become irregular or distorted, or the track gauge is no longer correct. Another possibility is that one or more of your railcars have wheels out of gauge or they are not the correct weight. Follow the NMRA standards on railcar weight, wheel gauge and coupler height. Also if you have lighter weight cars in the middle of the train and heavier cars on either end, you can develop a problem known as "string-lining" where the lighter cars in the middle are pulled off the track when the train goes around a curve.

Cleaning: This topic has been bantered around for years in the model railroad community. Many products have been made and sold and purchased in the name of track cleaning. According to Atlas technicians who manufacture tracks for model railroads, the best cleaning solution for tracks is plain old isopropyl alcohol (aka, "rubbing" alcohol that you can buy in the drug store). Use the same thing for cleaning wheels on locomotives.

Troubleshooting Your Model Railroad Scenery

We don't often think of scenery as something we need to troubleshoot. After all, it just sits there. It doesn't move - or does it? The answer is yes! It does move. And often ends up on the tracks causing a major pile-up somewhere in a remote, but critical, area of your layout that you have a difficult time accessing. I like having a lot of scenery, so I have had this problem of pieces of underbrush, falling trees, logs or rocks, etc. causing a crash or derailment more times than I can count. I use a lot of lichen and foam underbrush on the sides of my tracks in too many areas. Did you know that lichen re-expands after you've pushed it into place and glued it down? Sometimes, just the vibration of the trains running will result in a stray piece of something finding its way to your tracks, just when your 40 car coal hauler comes roaring through the area.

So, I've come to the conclusion having smooth-running trains is more important than having scenery anywhere close to the tracks. And for the hills next to your tracks, try to make sure all the brush, trees, grass, ballast, rocks, cinders and dirt are glued down as much as possible. This problem will still happen occasionally, but hopefully much less frequently. The prototypes have to deal with as well and often have to have a crew inspect the tracks every day in mountainous areas.

Consider cleaning your scenery every now and then by using a vacuum to suck up loose particles especially around tracks. To clean structures, use a very soft make-up brush to dust off the surfaces while holding a vacuum above where you are brushing. For "water" surfaces, use a damp foam brush to restore it to its original shine. If that doesn't work, you may wish to apply a thin coating of gloss matte medium.

Conclusion

So, I'm hoping that this page will be helpful to you if you've had any problems with your layout. Sometimes it's a slow step-by-step process to figure out what's wrong. You just have to patiently go through all the possibilities and eliminate each one until you find the culprit. This should also be an enjoyable process, a learning event, and one that you can share with others.

Back to Home Page

Contact Me | Blog | Photos | References | Supplies | GiftShop | Sitemap | Search | Comment | Privacy Statement | Disclosures

Tracks Newsletter: Sign Up Here!

√ = ad or sponsored link

What's New on BYMRR.com?

Recent Articles

-

Model Railroad Supplies

Dec 16, 25 03:46 PM

We have started a new store to help you build your layout and teach your youngsters about science with STEM products. -

DC and/or DCC on the Same Layout

Mar 09, 25 10:46 AM

How to wire your layout for either DC and/or DCC operation. -

Looking for a locomotive speaker

Nov 24, 24 07:29 AM

First Name: Randy E-Mail Address: bymrr@building-your-model-railroad.com Enter your question: : I am looking for a speaker for a Walthers EMD SD70ACE Locomotive, product number 910-9866. The control b…